Eric Kneller: The Prophet of Profit

The Profit Mastery Blueprint:

Slash Taxes, Double Profits, Retire Right!

Who We Are

Your profits are my passion!

We are on a mission to get Millions Back to Main Street! With over 45 years of combined business experience. Our dedicated team works as an extension of your business. You have to benefit first, guaranteed!

About us

Maranatha Consulting

As our Name implies, we are always praying for things to happen quickly. The Small Business Saver Framework is guaranteed to work for you if you: hire employees, purchase goods or services, pay taxes, own commercial property, or invest in property upkeep and maintenance. It will rapidly put anywhere from $200,000 to $1,000,000 plus onto your bottom line in year one

Savings are profits

Use funding to expand

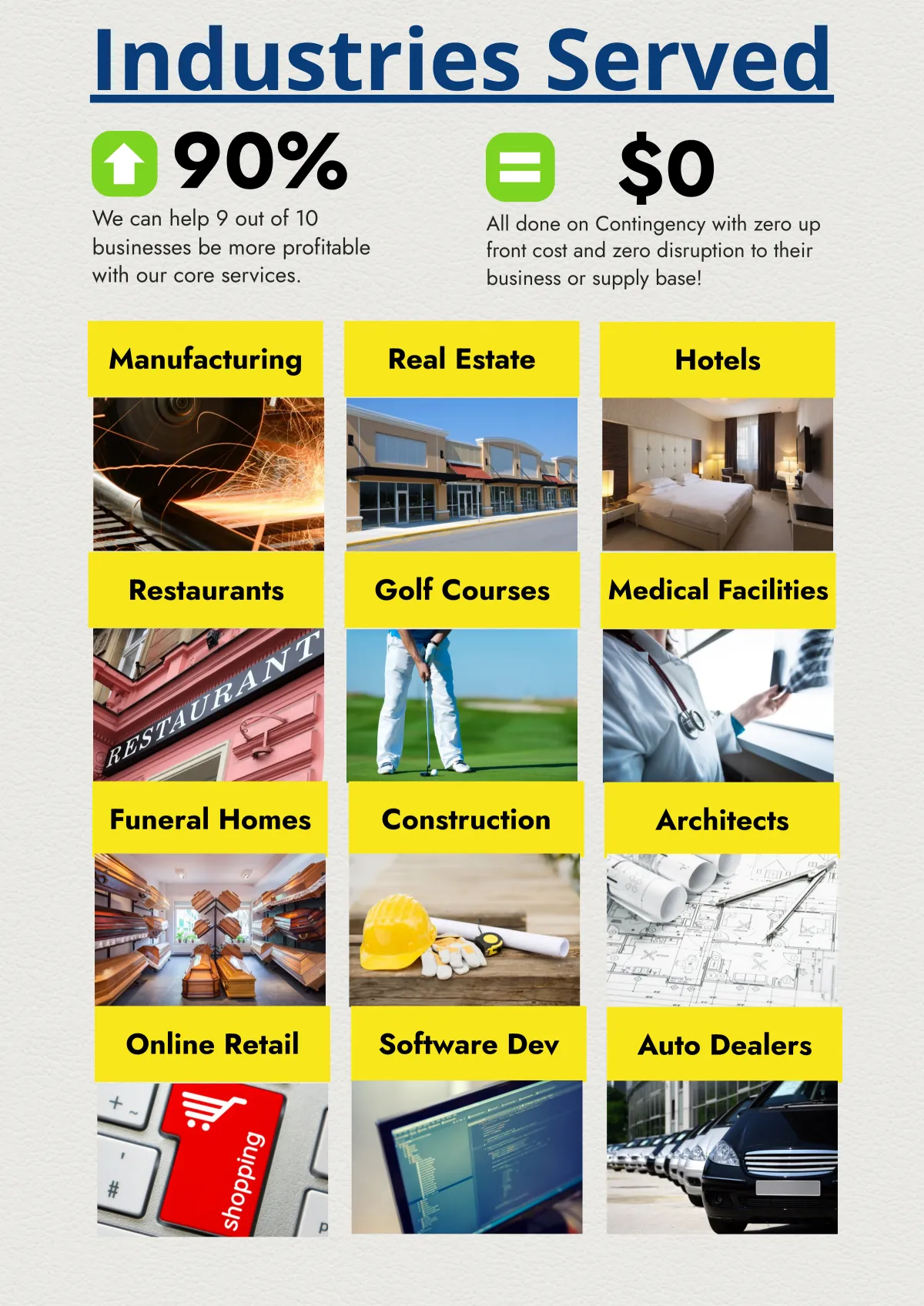

Industries Served

We can help 90% of businesses with 5-99 employees!

GET MILLIONS BACK TO MAIN STREET

Small Business Saver Packages

Take Advantage

6 Month Package

$0 Up Front

Identify Tax Incentives

Validated Savings

Property Taxes

Hiring Benefits

R&D Credits

Cost Seg Studies

Buy Better

12 Month Package

$5,000

Contingent

Tax Incentives

Strategic Sourcing

Contract Audits

Contract Negotiations

10X Savings Guarantee

Training

1 Day Package

$197

Online

Live & Recorded

CE Courses

Tax Incentives

Sourcing & Supply Chain

Exit Strategies

Slash Taxes

Power Purchasing

Fund Growth

Retire Right

Schedule a free 15 min review of The Profit Mastery Blueprint today and see just how much you can expect to gain this year!

The Small Business Saver

Eric Kneller

Latest Valuable Blog Posts

Can US Manufacturing recover?

“I don't spend my time pontificating about high-concept things; I spend my time solving engineering and manufacturing problems”

- Elon Musk

Introduction:

The contraction of manufacturing in the United States has been a significant issue at the start of 2023. According to data from the U.S. Census Bureau, manufacturing output in the country has declined for three consecutive months, with the sector experiencing its steepest contraction in over a decade. The contraction has been driven by a variety of factors, including rising inflation, hiring challenges, and supply chain disruptions.

One of the top issues facing manufacturers at the start of 2023 has been rising inflation. The U.S. economy has been growing at a robust pace over the past year, and this has led to an increase in the cost of raw materials and other inputs. For manufacturers, this has translated into higher production costs, which in turn has put pressure on profit margins. To combat the challenges of inflation, manufacturers have a few options. One option is to invest in more efficient production processes, which can help to reduce costs. Another option is to focus on developing new products or services that can command higher prices, which can help to offset the impact of rising costs. Finally, manufacturers can also consider hedging their exposure to rising prices through the use of futures contracts or other financial instruments.

A second major issue facing manufacturers at the start of 2023 has been hiring challenges. Despite the strong economy and relatively low unemployment rate, manufacturers have struggled to find qualified workers. One reason for this is that many manufacturing jobs require specific skills or experience, which can be difficult to find in the current labor market. To combat the challenges of hiring, manufacturers have a few options. One option is to invest in training and development programs that can help to upskill current employees or attract new workers. Another option is to focus on building a positive company culture that can help to attract and retain top talent. Finally, manufacturers can also consider partnering with local schools or training programs to help build a pipeline of qualified workers.

A third major issue facing manufacturers at the start of 2023 has been supply chain disruptions. The pandemic has disrupted global supply chains in a number of ways, including through the closure of borders, the suspension of transportation services, and the disruption of production facilities. To combat the challenges of supply chain disruptions, manufacturers have a few options. One option is to diversify their supply base, which can help to reduce the impact of disruptions to any one supplier. Another option is to invest in technology that can help to automate and streamline production processes, which can help to reduce reliance on external inputs. Finally, manufacturers can also consider implementing contingency plans that can help to mitigate the impact of disruptions to the supply chain.

Overall, the contraction of manufacturing in the United States at the start of 2023 has been a significant issue for the sector. Manufacturers have faced a variety of challenges, including rising inflation, hiring challenges, and supply chain disruptions.

To combat these challenges, manufacturers have a few options, including:

Investing in more efficient production processes

Developing new products or services, training and development programs

Building a positive company culture, diversifying their supply base

Investing in technology

Implementing contingency plans

By addressing these challenges, manufacturers can help to ensure that they remain competitive in a challenging market environment.

Testimonials

Frequently Asked Questions

Does My Business Qualify?

There is a 90% chance that the answer to that question is, "YES!" There are still provision of the CARES act that are offering tax incentives and rebates. And the truth is that most businesses are not taking advantage of certain incentives because they are outside the scope of work of their CPA or Accountant. That is not to say the CPA is not doing a fantastic job, he or she is just not focused on these specialized incentives and we are. We work alongside your CPA to help ensure you get as much as possible! There is zero risk to you and we promise that within the first 30 minutes (with the right information from you) we will be able to provide you with an estimate.

How Much Does It Cost For Me To Find Out If I Qualify?

$0 That's right...smile! We will work with you on complete contingency to find out how much The Profit Mastery Blueprint will save your business. We never take on clients we cannot help.

Are There Any Guarantees?

Yes! We guarantee that if you follow the steps in The Profit Mastery Blueprint you will: Slash Taxes and Increase Profits!

Get In Touch

Available Hours

Mon – Sat 9:00am – 8:00pm

Sunday – CLOSED

Phone Number:

908-797-2147

Office: Sarasota, FL

Call 908-797-2147